All in the name of efficiency

With many innovations, the injection molding machine manufacturer, ENGEL, has emerged from Schwertberg, Austria (near Linz) as a global market leader. When equipping your production, ENGEL focuses on an optimal cost/benefit ratio. Deliberate care is taken to invest in powerful machine technology.

4,500 employees and nearly one billion euros – key data for the global market leader of injection molding machines, ENGEL AUSTRIA GmbH. Since its founding 70 years ago, the company has remained 100% family-owned and independent of external investors. This leaves room for innovative ideas, like the tie-bar-less technology, for example: In 1989, ENGEL became the first machine manufacturer worldwide to introduce an injection molding machine with tie-bar-less clamping unit – a unique selling proposition that is still protected by patents to this day. With its large clamping area and easy accessibility to the tool area, tie-bar-less injection molding machines are ideally suited to meet the requirements of being highly efficient and cost-effective.

The successful tie-bar-less machines with more than 60,000 sales worldwide are just a part of ENGEL's broad portfolio: Machines from 280 kN to 55,000 kN clamping force, from hydraulic to all-electric, oriented horizontally and vertically. ENGEL has also evolved into a system supplier over the years, offering automation, process technologies, mold project planning, training, and services in addition to the machines. With more than 20,000 installed automation solutions, the injection molding specialist is also at the forefront of this field worldwide.

High productivity – including for their own manufacturing

The germ of these types of innovative product developments lies in the headquarters in Schwertberg, Upper Austria. Around 1,700 employees work here – more than at any other location. They handle the company's key duties, like design and development, sales, and marketing. However, the site in Schwertberg also houses the production of small and medium-sized injection molding machines with clamping forces up to 5,000 kN. This is the production facility that is responsible for a significant share of ENGEL's success.

It ensures the high quality of the machines and competitive prices. Gerhard Aigner, Head of Production in Schwertberg, bears responsibility for this: “We employ around 200 people who manufacture about 90% of all the mechanical parts at turn-mill centers. We stay competitive with other suppliers with regard to costs and quality, which is why we are continuously focused on the high performance of our machinery and we always push to improve. Continuous improvements at the site that results in added value can only result from very good and highly motivated employees, who come from the in-house apprenticeship workshops at ENGEL.”

One key to the cost-effective manufacturing is the complete machining of the parts to the extent possible in a single clamp. This requirement also plays an important role when replacing a CNC turning machine that was no longer productive enough for the people in charge of production. Gerhard Aigner explains: “We do not evaluate our machines by age, but by the productivity they achieve. We wanted to improve this with a new quickly and easily adjustable turn-mill center.”

Dual five-axis machining in one machine

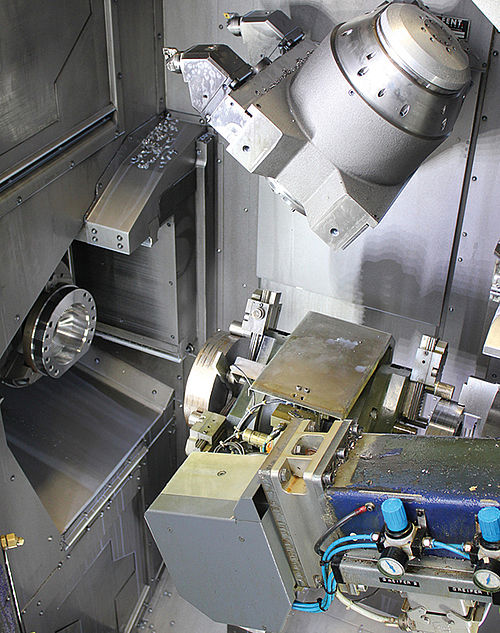

In the search for a suitable system, ENGEL became aware of the RatioLine series from INDEX, the design of which corresponded to what people in charge of production envisioned. The INDEX R300 turn-mill center, in particular, fulfilled their requirements. A key feature of this machine are the two independent subsystems that are each equipped with one motorized milling spindle (HSK 63, 24.5 KW, 9,000 rpm)

and one associated work spindle (52 KW, 3,500 rpm). This allows complex workpieces to be machines simultaneously and independently from each other – in five axes. Likewise, certain machine details contribute to the desired high flexibility with the available spectrum of machining and parts. For instance, with the two tool strips additionally mounted at the side of every milling spindle, the user has quick access to up to six fixed tools (VDI30) per spindle. This provides the versatility and performance of a milling spindle while approaching the functionality of a turret. The dual chain magazine can hold up to 140 tools that can be exchanged quickly by two independent tool changers in both motorized milling spindles, enabling chip-to-chip times under 6 s.

The INDEX R300 enables full rear end machining as well as parallel machining with identical sequences. Both heavy-duty roughing operations and highly accurate finishing operations can be performed simultaneously on the main spindle and counter spindle. Convincing qualities. After visiting INDEX in Esslingen, and intensive discussions, the team around Gerhard Aigner developed a good deal of trust in the R300 from INDEX-Werke, which – like ENGEL itself – is also a system supplier. They were one of the first customers to decide on the purchase of an R300, enhanced with a Promot workpiece handling system integrated into the machine. The Head of Production does not beat around the bush with the results: “Our early decision to procure this machine has paid off. It allowed us to reduce our manufacturing costs and gain ground against other suppliers.”

Reproducible signs of quality

Since December 2012, the INDEX R300 has been located in mechanical manufacturing 1, where a multitude of parts are machined continuously. The spectrum stretches over numerous components of the injection side and clamping side of an ENGEL machine. Parts made of chromium-nickel steel in most cases, that are designed to transfer forces and motions and also assume sealing functions as hydraulic components. The requirements with regard to concentricity, parallelism, and surface quality are correspondingly high. To Josef Büchsenmeister, Head of Manufacturing, the investment in the R300 was a direct hit: “The INDEX machine is a perfect fit for us and our manufacturing philosophy. It brings with it a high, reproducible base level of precision. That is the basis for being able to adhere to tolerances of 1/100 mm with repeat accuracy in a reliable process.” The high power density, with two motorized milling spindles and work spindles each in the smallest space, also fully met his requirements. There is also automation integrated into the machine, including the 15-workpiece pallet circulating system, which made it possible to establish multi-machine operation at ENGEL. His enthusiasm also extends to the large number of tools: “The turning center that we replaced was a turret machine on which we had to setup the tools with every part. With the R300, we can cut hundreds of parts without having to perform even a single tool change. This has increased the spectrum of parts enormously, and the setup times decreased considerably at the same time.”

"We were able to reduce the manufacturing time by up to 50%."

Added to that are the fixed to on the tool strips of both milling spindles. For Josef Büchsenmeister, that is an element that gives the INDEX R300 another competitive edge: “Together with our programming department, we worked out the optimal configuration for these fixed tool strips so we can ideally use them to perform heavy roughing operations and internal machining on the counter spindle.” Christian Leitner, Head of the CAM department, is also very happy with the new turn-mill center and the INDEX support: “We design our parts completely in 3D, and use the Siemens NX CAM system for programming and simulation. The simulation provides all of the important data before the part is manufactured. This brings us a step closer to production 4.0. It was important to preserve this process chain without diversions. The fact that INDEX was able to provide us with a special post processor was naturally an important argument for the INDEX R300.”

The ENGEL programming department had to adjust to the new dual spindle machine in the process. For some parts, the cutting passes had to be updated, the machining forces had to be distributed differently, and the cutting speeds had to be adjusted. The result, however, made the Head of Production, Gerhard Aigner, very happy: “We were able to reduce the manufacturing time for some parts by up to 50%. The complete machining also drastically reduced the idle periods for the parts. That is why at the end of 2014, we ordered another R-series machine from INDEX.” This was the somewhat smaller INDEX R200, which ENGEL can also automate.