Multitasking: More Than Doing Two Things at Once

Exceeding Expectations

Finding better, more efficient and more profitable ways to produce parts and keep a competitive advantage is a daily pursuit at successful shops. It’s no different at Task Force Tips (TFT), Valparaiso, IN, which makes multiple different sizes and designs of nozzles, valve bodies, and other components for fire suppression and water delivery equipment for the forestry, municipal, and industrial firefighting markets, as well as for aircraft deicing. As a result, TFT does many short runs of hundreds of different part designs.

Founded in 1971, the closely held company is dedicated to creating the means for firefighters to be as effective as possible in dousing flames, performing just about every task in-house from engineering through machining, assembly and testing. Within its fully integrated production plant, about 98% of the work is done in-house by more than 200 employees.

It is a highly team-oriented workforce and Chairman & CEO Stewart McMillan encourages employees to constantly think of better ways to do what they do. TFT invested in a range of automatic lathes from INDEX that creates opportunities for programmers and operators to come up with better processes. “INDEX created an opportunity that was game-changing for our company,” stated McMillan,

TFT runs six C Series automatic lathes that McMillan says produce parts you would think came off a machining center. According to McMillan, “There doesn’t seem to be a limit on what we can get them to do well.”

The company first invested in CNC machining in 1980. Since then, TFT has been continuously evaluating and adopting more advanced machines for increasingly automated processes.

Several years ago, TFT acquired an INDEX R300 simultaneous 5-axis turn-mill that has allowed the company to further reduce cycle times for key parts. Productivity has moved into a range they never could have imagined, despite their experience with top mill-turn machine tools. The result has been further improved part quality, even less processing time per finished part and greatly expanded production capacity in the well-equipped shop.

“The INDEX machines have made a fundamental shift in how we think on the machining side of TFT,” said Cory Mack, production supervisor.

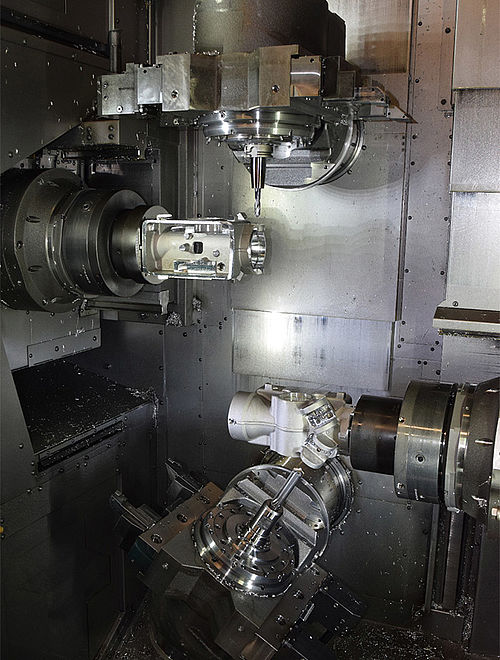

Following the success of its first R300, TFT purchased a second to further increase capacity. The R300 has two independent 5-axis subsystems, each with one motorized milling spindle and one assigned work spindle. This provides the ability to completely machine complex parts from short bars up to 102 mm and chucking up to 315 mm diameter, simultaneously. The machine is geared toward applications where larger chucked parts require a significant amount of milling and drilling work, such in the farm machinery, construction, moldmaking and aerospace segments.

From very simple to highly complex components, the main benefit is that complex machining operations can be completed simultaneously on the front and rear of the part via two highly productive motorized milling spindles.

Ideal for difficult milling operations, the R300 is also capable of hobbing or deep-hole drilling with single-lip tools, and can deliver high-pressure coolant of up to 80 bar to the tool edge through the motorized milling spindle.

Minimal Setup Times and Short Secondary Processing Times

On its INDEX R300s, TFT can carry out full rear-end machining as well as parallel machining with identical sequences. Both heavy-duty roughing operations and fine-turning operations can be completed simultaneously on the main spindle and counter spindle. By holding up to 140 tools in the double-chain magazine, the machine ensures short setup times, even for small batches. The tool storage capacity also allows TFT to store enough tools to completely process several different parts. Changeover is just a matter of choosing the program.

“The 12 stationary tools on the tool strips of both milling spindles bring the total number of available tools to 152, providing a nearly unlimited range of operations and machining flexibility,” Mack pointed out. Both milling spindles can perform tool changes completely independently of one another. The use of HSK tool holders reduces the tool costs as live tool holders are no longer necessary.

The option of running the machine with a short bar loader with minimal operator intervention is only one of several automated handling solutions. For a series of larger chuck parts, TFT has outfitted the machines with integrated robot loading.

A very rigid system, the R300 is less susceptible to vibration, which has a positive effect on the precision of the finished parts and on tool life. This allows TFT to produce clean, smooth surfaces and eliminate secondary deburring of critical bores.

The two quill-guided motorized milling spindles are located in the center of the machine bed. Due to the arrangement of the axes, conventional cross slides with tool carriers are no longer necessary. When combined with the play-free and wear-free hydrostatic circular guide, the system achieves very high stiffness.

The B-axis swivel range of 270 degrees and the rapid traverse rate of 45 m/min support machining flexibility and high-speed operation at TFT. The identical turning spindles with the same synchronous design have maximum power rating of 47 kW, maximum speed of 3500 rpm and peak torque of 690 Nm.

Multitasking Refined

According to McMillan, “We started this quest for efficient multitasking in the early ‘90s and lessons learned helped us move forward.”

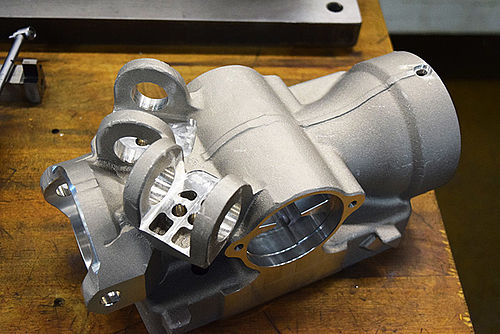

An example of this can be found in the Blitzfire XX600 aluminum nozzle body. When it was introduced by TFT, the company machined the part in four operations taking 2.5 hours per piece across two lathe operations and two mill operations.

“The first two operations on the lathe were boring and secondary boring plus milling some detail, all very time consuming,” Mack said. “The first operation was expensive because we had to have our highest paid personnel on it, setting it up and running it. The bore had to be indicated on each casting. Shimming the casting and tapping it around with a brass hand tool to get it located was how we got the initial correct runout set on the parts.

“The second operation was more finished, loading a part on a Positrol ID workholding. Then we performed two milling operations on a third machine because we could not get to all the features on the horizontal lathe without doing it in two operations.

“All these operations created burrs, which required a secondary manual deburring operation so it could be assembled. The operations and part handling amounted to 2.5 hours per part, not including deburring.

“Then we put the part on a DMG Mori NT multitasker, with one turret and one motorized milling head. At this point we also started using Esprit CAD/CAM software. Although the part was done in one operation, the cycle time was still about 35 minutes. It was a nice improvement for us, but the NT has some clearance issues in our case, and we could not get all the deburring done on it. And it had some extreme tool overhangs.”

It was at this point that McMillan saw the R300 at IMTS.

“When we put the XX600 on the R300, we were not looking for a tremendous improvement in cycle time, but we did like the possibility of simultaneous machining with two motorized milling heads,” said Mack.

“We put some of our larger volume parts, of up to 5,000 parts per year, on the machines. These were couplings and nozzles that require a range of milling, turning and threading operations. With the tool capacity, the machines can work unattended. The two R300s eliminate the need for four multitasking machines,” Mack said.

Unexpected Benefits

“We discovered the R300 provided a lot more opportunity for process improvement than we expected,” said Mack. “We could do simultaneous complete machining, reaching all the features of the part plus a deburring pass, all in one setup. This got the XX600 done in 15 minutes complete, including deburring, so we saved not only cycle time but man-hours in deburring.

“We then added a loading robot. Parts are staged and the robot self-loads. This allowed very good process improvement on this part.

“Once you have the machine programmed and take the human element out of the operation by eliminating deburring, you really save time. It is like a free operation.

“We thought we could shorten the cycle time, but we had not considered the rigidity of the machine and its positive effect on the part quality and the capability of the two milling heads for simultaneous machining. Plus, the tool magazine location and capacity supports faster, more complete processing of our parts. Even simple parts are run faster.

“With the greater machining capability, our design engineers started picking up on what the manufacturing floor can do. In my experience, it is almost like the engineers have a feel for what we can do and design parts to take advantage of that. The result is improved designs and improved quality for our customers.”

Controller and Software Packages with User-friendly Functions

The INDEX control C200-4D SL is based on the Siemens Sinumerik S840D solution line and was enhanced by INDEX with user-friendly features. Specially developed cycles simplify even the most complex machining operations, supporting multi-axis milling and turning operations and providing maximum functional reliability.

“There are so many features of the Siemens control that, when tied to Esprit software, made it the easiest machine to setup of all the mill-turns,” said Mack. “Our programmer has told us that when he looks at a part that he does not think will run faster on the INDEX machines, he ends up cutting the time in half. And when he sees a job that is well-suited, he can cut the time by as much as 70 percent.”

Programming: Not So Tough

Brandon Marcotte, R300 operator and programmer, championed the machines. An experienced INDEX machine operator, Brandon is a young man that came to TFT with an interest in machining and is now operating C Series automatic lathes, as well as the R300s.

“Learning programming to machine theXX600 was not difficult,” Marcotte said. “We split the program into two-part simultaneous with the R300 to get the time to 14 minutes. The robot with 10 kg capacity loads one part at a time, taking a finished part off while the machine internally transfers the part from one side to the other. It seems like a big animal, but it was not really.”

According to Marcotte, “The biggest challenge when programming the INDEX machine is balancing the workload between the two heads so we could get the most benefit out of the machines, such as changing fixtures, for example. I didn’t feel the programming was too much of a challenge, as it’s just two milling heads on spindles. We were familiar with the control. We have used both Siemens and Fanuc. In our experience, the Siemens is quicker and more advanced without over-complicating the process.

“We got the INDEX Virtual Machine simulation software before we got the R300. We installed it on my computer so that I could work with the fully simulated machine before it even got here. And we could write posts for the machine before it arrived. So we knew what we were posting out of the CAM software would not alarm-out the machine.”

The INDEX Virtual Machine software makes the turn-mill center efficient to operate right from the very first workpiece. It guides the NC programmer and operator to the right solution for the machining task – both on the PC during the preparation stage and directly at the machine in the factory. With 3D simulation, machining programs can be created, verified, and optimized on the PC.

“Virtual Machine made it one of the smoothest machine installations we’ve ever had, and because it’s specific to the machine, it is fully reliable,” Marcotte said. “It is the machine control itself, unlike other general programming simulation software.”

“All this capability has put us very far ahead in machining capacity, the ability to do more,” said Mack. “It’s not that we bought a ton of new machines. It’s that we bought the right machines. “

It all started with McMillan’s vision on what the company could do with the right machines. At TFT, the INDEX machines actually help conserve valuable capital dollars for the company and permit it to turn out very high quality parts in short cycles, resulting in lower per-piece costs.