Making Complex Parts Profitably

“Over 20 million manufacturing jobs have been transferred to Asia since I started in 1973. Today, there is almost no metalcutting manufacturing here in Massachusetts short of some medical and some aerospace’” says Jake Grainger, owner of Alpha Grainger, Franklin, MA. “There is either a strategic reason for making it here or it is what I call protected work: firearms, defense, or expensive mechanical devices. Any commodity part is gone. There is no ’coming back’ or re-shoring. All that has happened is temporarily coming back until it can be made correctly in Asia.”

So how does a precision parts shop make a profitable go of it in the United States these days?

“I had to figure out a way to win what was left of the work here in this country—the tough, complex parts that are too much of a challenge for most shops that may be accustomed to simpler work. If we wanted to stay in business we needed to be able to go after it successfully and profitably. Multi-spindle CNC’s let us complete a part with many small details and features in 10% of a single-spindle lathe cycle time.”

After some pretty intensive research, Grainger decided on INDEX multi-spindles.

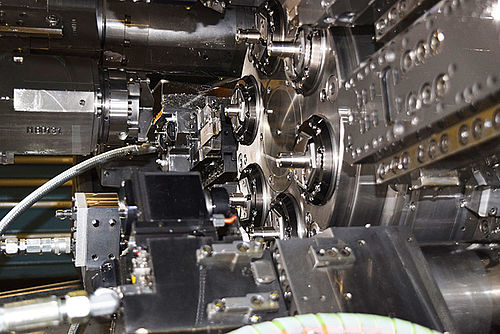

“We now have three six-spindle INDEX MS40’s and three eight-spindle MS22-8 multis. I decided to buy four of the 22-8’s at once because we felt we had to make the investment to get that leap ahead—not one now and another in a couple months and another in nine months. Our decision was to bring in technology immediately and build the multi department now.”

Grainger has an unconventional view of the place of the multi-spindles in the range of metalcutting machine tools.

“I think of the multis as a multi-spindle milling machine with lathe capability rather than a turning machine. We have a hard time winning jobs that are just turning. We need ‘stop-spindle’ work. If it is just straight turning, someone else will win it. It’s brutal. There is a dogfight for the simple work: drilling, tapping, turning. There are a lot of shops that will do it inexpensively--not enough to pay people good wages and benefits.”

Where do the shop hands come from?

“We are unable to hire anyone that is ready walking in the door. So we have an informal mentoring program for new hires which can last as long as it takes,” Grainger said. “Getting skilled people is still the hardest thing we do. Our educational establishment does not bring up the mechanically oriented person. So we prospect in the automotive repair area for new hires.

“The multis can be a bit intimidating at first, but most new people will try to learn the machine as they are unwilling to show they are not up to the challenge. I had to figure out CNC machine tools myself because there was no one to teach me. After a couple days, they get past that and their effectiveness grows. The INDEX takes a well-trained person to run it, but unless you build that kind of capability in your precision shop, you won’t compete successfully.”

Swiss in the Crosshairs

About 9,000 Swiss-style machines have been sold since the 1980’s and most are still good machines, in Grainger’s view. The process is one of the most reliable in the industry, and can be run for low hourly rates. In the turned parts market, the lowest price wins.

“Part of my job is to know every machine tool out there and to figure out how it could help us. I am the Chief Technology Officer of the company,” Grainger observed. “I am constantly looking for processes that that are much more competitive than anyone else. I don’t want to compete with the lowest rate.

“For us, customers of a certain volume of parts per year are what are interesting to us--non-obvious work on a lathe that looks like it came off a machining center.

“The INDEX machines have given me a way to be more productive than anyone else – more accurately, faster, more reliably,” Grainger said. “And the MS22-8 has given me the chance to achieve cycle times that are so short – in stop-spindle work – that I can take any job away from a Swiss shop.”

The INDEX MS22C-8, a modular eight-spindle machine opened up additional opportunities for already quick multi-spindle parts machining, especially highly complex parts for the automotive, defense, aerospace, mechanical, and medical industries. It also produces small batches efficiently and economically--bar-fed or loaded with chucked parts.

The main advantage of the MS22-8 is that it can be configured to operate as an eight-spindle machine, a double four-spindle machine that drops two complete parts at a time or a machine with double rear-end machining.

When Grainger finds a part that is in the range of 7/8 dia., because he can make it in 10% of the cycle time, he can win the work. Many times the work is so complex that Alpha Grainger uses a 3D printer for illustrating a part defined by six pages of prints, allowing the company to see how it has to be processed and accurately quote it. This is more important as parts become more complex, such as a component that takes 63 tools to process, using double and triple gang tooling.

The use of creative tooling to accomplish multiple operations in a single spindle is also a key advantage of the CNC multi-spindles. The MS22-8 hits a sweet spot for parts less than 1” diameter. With the eight-spindle capability, Alpha Grainger can win work Grainger says he never thought it could.

“The double pickoff spindle version is to me revolutionary because although all multi-spindles can accept a drill in each spindle, with the MS22-8 you have two cycle times to get the back work done, so you have a huge increase in spindle time available to do the work with three plus ten tools available. The pick-off work rarely takes more time than the main spindles do.

“It would be a terrible mistake if you did not buy the double pick-off, because then you can run the multi as two four-spindle multi-task machines,” Grainger says. “This wins me all kinds of work because there is no such thing as a four-spindle multi. A lot of parts can be made on a four-spindle multi. The only limitation is how many tools you can use.”

The MS22C-8 can perform turning, off-center drilling and thread cutting, inclined and cross-drilling, milling, multi-edge turning, hobbing, tooth milling, deep-hole drilling and slotting. Another benefit for the user is that all standard tool holders and tool holder system interfaces can be used with a range of popular adapters, including Capto, HSK, VDI, INDEX systems.

Each of the eight spindles, arranged in the well-known INDEX spindle drum, are assigned two cross slides which can travel on both the X and Z axes. Each cross slide can also be equipped with a Y-axis.

Up to two swiveling synchronous spindles permit simultaneous rear-end machining. Combined with a total of up to 16 cross-slides, the eight-spindle machine is well-suited for highly complex machining.

The speed of each of the eight liquid-cooled spindles can be controlled separately. The fluid-cooled spindle drum keeps the thermal growth in the spindle carrier to a minimum, resulting in higher power density in the spindle drum and the ability to recover the heat energy from the cooling fluid. The spindle bearing temperature can thus be kept at a low level, which also prolongs service life and improves thermal stability. The INDEX multi-spindles avoid thermal expansion with a 40kw chiller.

The cross slides with integrated drives have a low-mass design with hydrostatic bearing support. Their low moment of inertia and resulting high dynamics facilitate outstanding acceleration in operation.

The MS22C-8 in double four-spindle mode actually runs as two machines working simultaneously on a single base. Every second tool station always has simultaneous access to the same tools.

When operated as an eight-spindle machine, the drum indexing angle from spindle to spindle is 45°. If the machine operates with two times four spindles, the drum indexing angle is 90°. The double four-spindle means two finished parts are produced by the machine per work cycle.

In double rear-end machining, there are six spindle positions available for front machining the workpiece and two spindle positions for rear-end machining, and they all work simultaneously. With this approach, you can machine the rear end of a workpiece during two drum indexing cycles.

After front machining, for which six spindle positions are available, workpieces are picked up by two rear machining units and machined simultaneously on the rear end.

Because rear-end machining is done during two drum indexing cycles, up to six tools can be used for this simultaneously with the other spindles. With all cross slides located at the same travel angle to one another, free chip flow is guaranteed in each position.

At Alpha Grainger, Grainger and his crew are making a lot of progress using the MS22-8 as a double-four multi-spindle.

“Now I have four CNC cross slides that can do almost any operation you need to, so it opens the door to a huge amount of product that I can make in the double-four configuration. It is a long way from the old Brown and Sharpe’s, which were great in their day, but had only three non-CNC cross slides. All of a sudden I can compete on work that I previously thought was too cheap or low-cost. One of our multis is set up for a valve body. We beat the Chinese supplier on that product using the double-four configuration.”

To prove a process like that, Alpha Grainger can use its INDEX C200 automatic lathes.

“We win that kind of machining center work with our INDEX C200 automatic lathe, demonstrating better cycle times and lower part cost compared to machining centers. Machining centers have multiple loads, fixtures, etc. When we move the part to a multi, we can reduce our cycle times further. They give me capability that you can get nowhere else, and they are astoundingly accurate. There is no dimensional variation.”

Design Features for Consistent Machining

The advantage of a hydrostatic sliding guide in the feed (Z) axis is the outstanding damping characteristic that prevents the transfer of the machining vibrations to the adjacent slide via the headstock. This helps to mitigate vibration and rattling while workpieces are being machined, even when the most diverse machining processes are being performed concurrently by the eight spindles.

For example, one spindle can be used for heavy-duty roughing while high-precision finishing takes place on another spindle without sacrificing surface quality. In addition, the hydrostatic bearing is wear-free. There is neither friction nor a stick-slip effect.

The swiveling synchronous spindles are locked into the end positions by three-part Hirth couplings. The high level of stiffness that this achieves also guarantees that, even with bar diameters up to 24 mm, rear-end machining operations can be performed with very high cutting volumes and high machining precision.

The Hirth coupling also means it is no longer necessary to electronically compensate at the end position. The mechanical lock ensures optimal stiffness and increases the positioning accuracy. This allows even highly complex components that require complex cut-off side machining to be produced. The swivel movement to the rear-end position occurs in less than 0.3 seconds.

For operators, the advantage of the INDEX multi-spindles’ front-opening design is the excellent accessibility during setup and tooling. Moreover, there is free chip flow down into the chip discharge chute.

For discharging workpieces damage-free from the work area and placing them on pallets in the right position for later treatment, the MS22C-8 can include optional handling solutions. These include machine-integrated handling with an external stacking unit that ensures careful removal of parts from the machine, including measuring operations for the workpieces if needed. Workpiece data can be fed directly back to the machine control so it can automatically correct its machining parameters.

The decision to invest in multi-spindle CNC’s was a big one for Alpha Grainger, but Jake Grainger’s vision of the future of precision parts manufacturing required nothing less.